Why Catalytic Converter Recycling Matters

Environmental sustainability and resource recovery have become critical priorities in today’s economy. According to the Environmental Protection Agency, automotive catalytic converters contain precious metals worth billions of dollars annually, making their proper recycling essential for both environmental protection and economic recovery. Understanding the catalytic converter recycling process has never been more important.

Recohub combines cutting-edge technology with transparent business practices to deliver exceptional value to our clients. Our comprehensive approach to catalytic converter processing ensures maximum recovery rates while maintaining the highest environmental standards.

Understanding Catalytic Converter Composition and Value

The Science Behind Precious Metal Recovery

Modern catalytic converters contain three primary precious metals that drive their recycling value. Research published by the Journal of Cleaner Production demonstrates that platinum group metals (PGMs) in automotive catalysts can be recovered at rates exceeding 95% through advanced recycling processes.

Platinum serves as the primary oxidation catalyst, while palladium proves more effective in gasoline engines, and rhodium specializes in reducing nitrogen oxides. These metals maintain their catalytic properties indefinitely, making their recovery through catalytic converter recycling both environmentally responsible and economically viable.

Different vehicle types yield varying precious metal concentrations. Diesel engines typically contain higher platinum concentrations, while gasoline engines feature more palladium. Understanding these variations helps determine accurate catalytic converter price assessments.

The Professional Recycling Process

Assessment and Identification

Professional identification begins with comprehensive visual inspection and serial number verification. Our team utilizes advanced spectroscopy equipment to determine exact metal content, ensuring precise valuation. This scientific approach provides accurate catalytic converter scrap price assessments based on actual metal content.

Proper identification requires expertise in recognizing different converter types. Vehicle make, model, year, and engine size all influence metal composition. Our database contains detailed specifications for thousands of different catalytic converter configurations, enabling precise identification and fair pricing.

Market-Based Pricing

Market-based pricing reflects real-time precious metal values from major commodities exchanges. The London Metal Exchange provides benchmark pricing that forms the foundation of our valuation system. Daily fluctuations in platinum, palladium, and rhodium prices directly impact catalytic converter price calculations.

Transparency remains central to our pricing methodology. Clients receive detailed breakdowns showing metal content, current market prices, and recovery rates. This approach ensures fair compensation while maintaining trust throughout the recycling process.

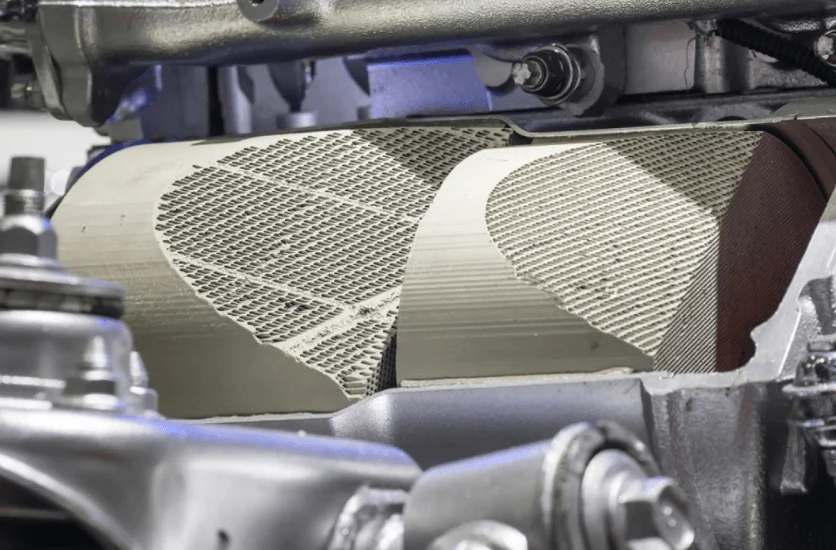

Advanced Processing and Metal Recovery

Our state-of-the-art facilities utilize pyrometallurgical and hydrometallurgical processes to achieve maximum metal recovery. Research from the International Journal of Mineral Processing confirms that combined processing methods can achieve recovery rates exceeding industry standards.

Temperature-controlled smelting separates precious metals from ceramic substrates, while chemical leaching refines individual metals to investment-grade purity. Environmental controls ensure zero emissions during processing, meeting all EPA requirements.

Choosing the Right Catalytic Converter Recycler

Industry Certifications and Compliance

Legitimate catalytic converter recycler operations maintain extensive certifications demonstrating environmental compliance and processing capabilities. The International Organization for Standardization ISO 14001 certification ensures environmental management systems meet international standards.

Recohub holds all necessary permits for precious metal processing, including EPA waste handling authorizations and state-specific recycling licenses. Our facility undergoes regular third-party audits to verify compliance with environmental regulations and industry best practices.

Technology and Processing Capabilities

Modern recycling facilities require sophisticated equipment for efficient metal recovery. X-ray fluorescence spectrometry provides non-destructive metal analysis, while inductively coupled plasma mass spectrometry confirms precise metal concentrations. These technologies ensure accurate catalytic converter scrap price determinations.

Advanced sorting systems and efficient handling procedures minimize processing time while maximizing recovery efficiency.

Logistics and Payment

Collection Services

Professional collection services eliminate transportation risks while ensuring proper handling. Our logistics network provides convenient pickup services for businesses and individuals. Secure containers and reliable tracking protect valuable materials throughout the collection process.

Documentation requirements include detailed inventory sheets, chain of custody forms, and transportation manifests. These records satisfy regulatory requirements while providing complete transaction transparency.

Payment Processing

Electronic payment systems provide fund transfers upon processing completion. ACH transfers, wire transfers, and check payments accommodate different client preferences. Payment timing depends on processing complexity, with most transactions completed within 24-48 hours of material receipt.

Detailed settlement statements accompany all payments, showing metal weights, purity levels, and price calculations. This documentation provides complete transaction records for accounting and tax purposes.

Environmental Impact and Sustainability

Catalytic converter recycling supports circular economy principles by recovering valuable resources for reuse. The Ellen MacArthur Foundation emphasizes that circular business models reduce raw material extraction while minimizing environmental impact.

Studies published in Environmental Science & Technology demonstrate that recycling precious metals produces 85% fewer carbon emissions compared to primary mining. Our processing methods further reduce environmental impact through energy-efficient technologies.

Conclusion: Partnership for Sustainable Success

Selecting the right catalytic converter recycler requires careful consideration of processing capabilities, environmental compliance, and pricing transparency. Recohub combines advanced technology with responsible business practices to deliver exceptional value while supporting environmental sustainability.

Our commitment extends beyond simple material processing to encompass complete client support throughout the recycling journey. From initial consultation through final payment, our team provides expert guidance and transparent communication.

Whether you represent an automotive service center, scrap dealer, or individual vehicle owner, Recohub offers the expertise and resources necessary to maximize your catalytic converter recycling returns. Contact our team today to discover how professional partnership can transform your recycling experience while contributing to a more sustainable future.

FAQ

1. What factors determine catalytic converter scrap price?

Catalytic converter scrap price depends on several key factors: the type and quantity of precious metals (platinum, palladium, and rhodium) contained within the converter, current market prices for these metals, and the vehicle’s make, model, and year. Diesel vehicle converters typically contain more platinum, while gasoline engines have higher palladium content. Market fluctuations on exchanges like the London Metal Exchange directly impact daily pricing, making professional assessment crucial for accurate valuation.

2. How do I identify my catalytic converter type for recycling?

Professional identification requires examining the converter’s serial numbers, physical characteristics, and vehicle specifications. Different manufacturers use unique designs and metal compositions that affect recycling value. Our team uses advanced spectroscopy equipment to determine exact metal content, ensuring precise catalytic converter price assessments. Vehicle information including make, model, year, and engine size helps identify the specific converter type and its precious metal composition.

3. What should I look for when choosing a catalytic converter recycler?

Select a catalytic converter recycler with proper certifications, transparent pricing, and advanced processing capabilities. Look for EPA compliance, ISO 14001 environmental certification, and state-specific recycling licenses. The recycler should provide detailed documentation, use scientific testing methods for metal analysis, and offer competitive pricing based on real-time market data. Professional facilities maintain proper environmental controls and provide secure collection services.

4. How long does the catalytic converter recycling process take?

The catalytic converter recycling timeline varies based on processing complexity and facility capacity. Initial assessment and identification typically occur within 24 hours of material receipt. Advanced processing methods including pyrometallurgical and hydrometallurgical techniques require additional time for complete metal recovery. Most transactions complete within 24-48 hours, with payment processing following immediately after final evaluation and documentation.

5. Is catalytic converter recycling environmentally beneficial?

Yes, catalytic converter recycling provides significant environmental benefits by recovering precious metals for reuse instead of mining new materials. Studies show that recycling precious metals produces 85% fewer carbon emissions compared to primary mining operations. Each catalytic converter contains valuable platinum group metals that maintain their catalytic properties indefinitely, supporting circular economy principles and reducing environmental impact through resource conservation.