Introduction: Representative sampling is the single biggest factor behind fair assays and payouts on converter lots. This guide explains what to do before, during, and after sampling so your lab gets a true picture of precious metals content and you get paid accurately.

- Clarify why representative sampling protects value and trust

- Show practical steps to homogenize batches and reduce bias

- Explain clean packaging, labelling, and chain-of-custody

- Connect sampling errors to shifts in catalytic converter price

- Outline reasonable acceptance criteria for samples and data

- Offer a simple action plan and audit checklist

Why representative sampling matters

Every batch of converters varies. Models, mileage, engine type, and prior handling all swing the precious metals distribution. A small, biased grab can miss that variation. Homogenized, statistically sound sampling reduces noise and aligns the assay with the true lot average.

Industry guides emphasize this. Modern samplers grind and mix ceramic to a uniform particle size before pulling multiple increments for the lab. That workflow is the backbone of reliable assays and fair payment across the trade. See a concise industry overview and why homogenization underpins settlement accuracy in this resource on catalytic converter recycling processes. PMR’s overview of converter recycling and sampling.

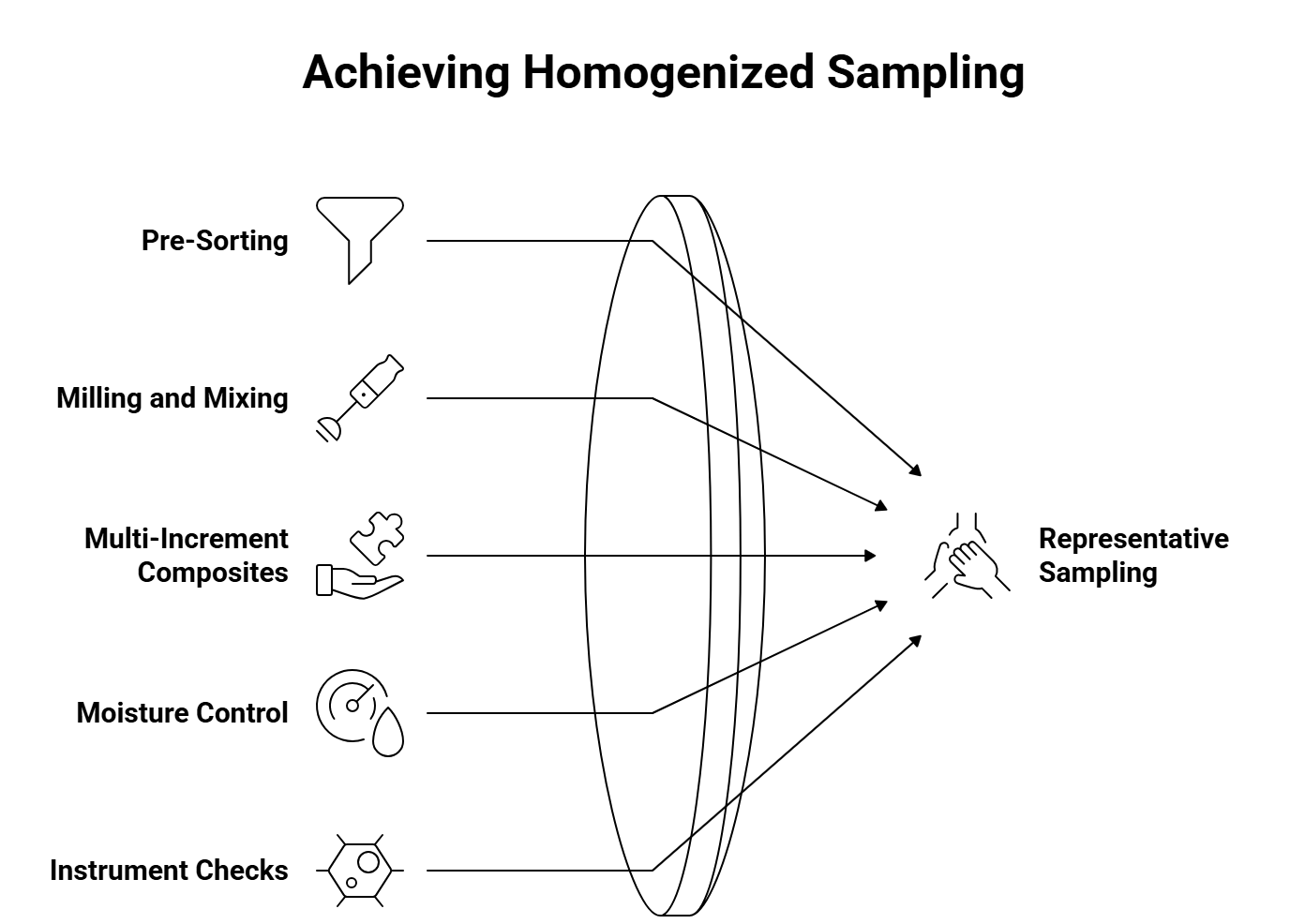

Methods for homogenized sampling on batches

1) Pre-sort by type and state

Group by substrate (ceramic vs metal foil), OEM vs aftermarket, and visibly damaged vs intact. Keep DPFs separate from three-way converters. Sorting reduces within-group variance and improves the representativeness of sample increments.

2) Decan, mill, and mix thoroughly

After safe decanning, mill ceramic to a consistent size. A target where the majority passes a fine screen helps the mix behave like a uniform material. Use a clean mixer to blend for several minutes, scraping sides to avoid pockets of coarse or fine material. Pull increments across the entire stream or drum at timed intervals rather than from one spot.

3) Use multi-increment composites

Build one composite sample per sorted group from many small increments. More small bites beat one large scoop. Label each composite with batch ID, item count, and mass.

4) Control moisture

Moisture changes weight and element readings. Air-dry or use controlled low-heat drying before final mixing and sampling. Record moisture loss on a small parallel split to correct assays if needed.

5) Instrument checks

For screening, handheld XRF can guide you, but final values should rely on lab-grade methods like ICP after proper digestion. Reputable lab protocols detail milling, homogenization, duplicate splits, and calibration standards to avoid bias. See a technical outline of decanning, milling, and QC steps here: laboratory sampling and testing protocols.

Packaging and labelling to avoid contamination

Cleanliness protects your data. Use new, sealable bags or sterile sample jars. Avoid recycled sacks that shed dust from prior jobs. Wear nitrile gloves, swap them between batches, and clean any scoops or funnels before use.

On each container, write a unique ID, batch description, material type, gross weight, and sampling date. Put the same data on a waterproof card inside the outer bag in case the label smudges. Create two splits: a lab sample and a retained reference. Seal both. Photograph every bag with the label visible to maintain a simple chain-of-custody record.

How sampling errors affect catalytic converter price

Assay drives settlement. If the composite under-represents high-value units, the calculated metal content drops and your expected return falls. Over-representing a single valuable model can swing the estimated value in the other direction and cause disputes after final refining. Either way, skewed sampling shows up later as a mismatch between expectation and settlement.

Consider common pitfalls:

- Grab-only sampling from the top of a drum misses fines that often concentrate PGM dust. That undercuts the catalytic converter scrap price you expect to see modeled in the assay.

- Wet material weighs more but can read lower until moisture correction is applied, which clouds comparisons across batches.

- Large chunks that dodge milling can hide undigested PGM, reducing measured values at the lab stage.

The effect is not subtle. Industry articles detail how a few percent swing in measured PGM can change valuation tiers and payment structures, which is why modern programs insist on blended composites and duplicate testing. A practical explanation of the assay flow and why representativeness is critical is summarized here: the importance of assay in recycling catalytic converters.

Homogenization playbook: a quick reference

| Sampling step | What it does | Common error | How to fix it |

|---|---|---|---|

| Sort by type | Reduces variability inside each group | Mixing DPFs with three-way cats | Separate and label groups clearly |

| Mill to uniform size | Improves blend and repeatable splits | Leaving coarse chunks in the mix | Screen and re-mill outliers |

| Timed multi-increment sampling | Builds a true composite | One scoop from the top layer | Pull small increments across time and location |

| Moisture control | Prevents weight and assay distortion | Bagging wet powder | Air-dry, record moisture loss on a split |

| Duplicate splits | Checks repeatability | No retained sample | Keep a sealed witness split |

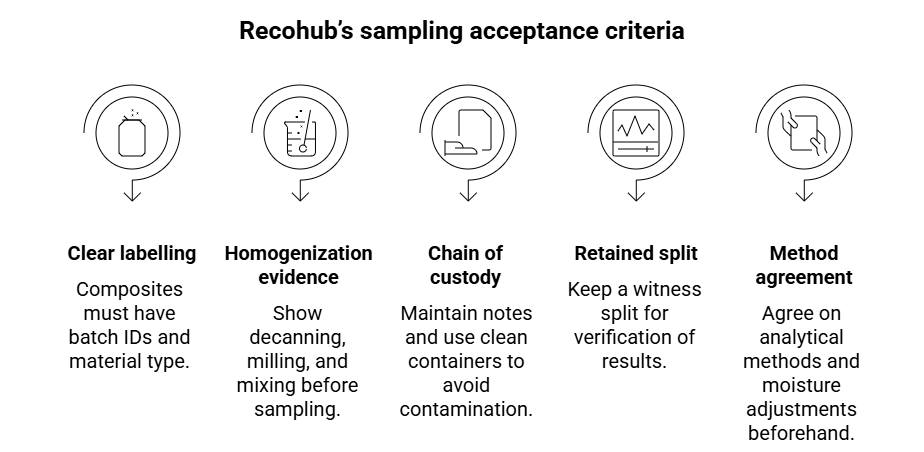

Recohub’s sampling acceptance criteria

Recyclers and labs usually look for simple, verifiable basics rather than rigid thresholds. Typical acceptance points include:

- Clearly labelled composites with batch IDs and material type.

- Evidence of homogenization – decanned, milled, and mixed – before sampling.

- Chain-of-custody notes and clean containers that avoid cross-contamination.

- A retained witness split for verification if results are questioned.

- Agreement on analytical methods and any moisture adjustments in advance.

If you are new to this or scaling up, start by aligning your intake sort, milling, and compositing steps with the outline above. Then document it. A one-page SOP and photos of each batch at each step go a long way.

Related reading and context

If you are sourcing material, see this guide to where to find catalytic converters across different markets and supply channels. For teams training staff, understanding catalytic converter precious metals and why they matter helps explain why sampling is handled with lab-like care.

Action plan: schedule a sampling audit

Here is a simple path you can implement this week:

- Map your current flow – intake, sort, decan, mill, mix, sample, package.

- Pick two recent batches and run side-by-side composites with better mixing and timed increments. Compare results.

- Create a two-page SOP with photos. Train the team and assign a sampling lead.

- Set up duplicate splits and a moisture log. Keep them for 90 days or your chosen window.

- Invite a third-party review to walk your process and spot blind spots.

If your goal is a cleaner settlement variance and fewer disputes, a short audit pays for itself in saved time and tighter results. For end-to-end support with compliant collection, decanning, milling, and settlements, explore catalytic converter recycling. If you prefer a managed partner approach, a seasoned catalytic converter recycler can benchmark your workflow and set up training and spot checks.

Summary

Representative sampling becomes simple when you control five levers: sorting, milling, mixing, multi-increment composites, and clean packaging. Do those well, and the assay reflects reality, which stabilizes expectations around catalytic converter price and reduces noise at settlement. If you want a second set of eyes on your process, our team can review your SOPs, suggest practical changes, and coordinate lab testing without interrupting daily operations.

FAQ

What’s the fastest way to improve sampling tomorrow?

Mill finer, mix longer, and collect more small increments across time rather than one big scoop. Those three changes deliver immediate gains in representativeness.

Should I rely on handheld XRF for payment?

Use handheld XRF as a screening tool. For settlement, rely on properly digested samples analyzed by lab instruments like ICP, supported by documented sampling and moisture controls.

How big should a composite sample be?

Big enough to include many increments and allow for lab analysis plus a retained split. The exact mass depends on your lab’s method. When unsure, ask the lab for the minimum sample size and create a duplicate split.

Do I need to dry every sample?

Not always, but you must track moisture. Either dry before sampling or record moisture loss on a parallel split so results can be corrected consistently.

Where can my team learn more about converter materials?

Training improves results. A clear primer on precious metal content and substrate types helps your samplers make better decisions at the pile, during milling, and at the mixer.