The catalytic converter is a pivotal component in modern vehicles, playing a crucial role in reducing harmful emissions and contributing to a cleaner environment. Understanding the technology behind catalytic converter production can offer valuable insights into how these devices work and why they are essential.

What is a Catalytic Converter?

A catalytic converter is an emission control device that converts toxic gases and pollutants from an internal combustion engine into less harmful pollutants by catalyzing a redox reaction (an oxidation and a reduction reaction). The main pollutants tackled by catalytic converters are carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx).

Production Technology

The production of catalytic converters involves several key steps:

- Substrate Preparation: The substrate is usually a ceramic or metallic honeycomb structure that provides a large surface area for the chemical reactions to take place. Ceramic substrates are typically made from materials like cordierite, while metallic substrates are made from stainless steel or other alloys.

- Washcoating: The substrate is coated with a washcoat material that increases its surface area and enhances the distribution of the catalytic materials. The washcoat is usually composed of aluminum oxide, titanium dioxide, silicon dioxide, or a mixture of these materials.

- Catalyst Application: Precious metals such as platinum (Pt), palladium (Pd), and rhodium (Rh) are applied to the washcoated substrate. These metals act as catalysts to facilitate the chemical reactions that convert harmful emissions into less harmful gases. The selection and ratio of these metals are crucial for the efficiency and durability of the catalytic converter.

- Canister Assembly: The coated substrate is then enclosed in a metal canister that is designed to withstand high temperatures and corrosive conditions. The canister also helps in the efficient flow of exhaust gases through the substrate.

- Quality Control: Rigorous quality control measures are implemented to ensure the catalytic converters meet emission standards and performance criteria. This involves testing for structural integrity, catalytic activity, and resistance to thermal and mechanical stresses.

Advances in Catalytic Converter Technology

Recent advancements in catalytic converter technology focus on improving efficiency, reducing the amount of precious metals used, and enhancing durability. Some notable innovations include:

- Advanced Coating Techniques: New methods for applying washcoats and catalytic materials improve the distribution and adherence of the catalysts, leading to better performance and longevity.

- Enhanced Substrates: Developments in substrate materials and structures aim to increase surface area and thermal stability, improving the overall efficiency of the catalytic converter.

- Multi-Functional Catalysts: Researchers are exploring catalysts that can perform multiple functions, such as reducing NOx and oxidizing CO simultaneously, to streamline the catalytic process and reduce costs.

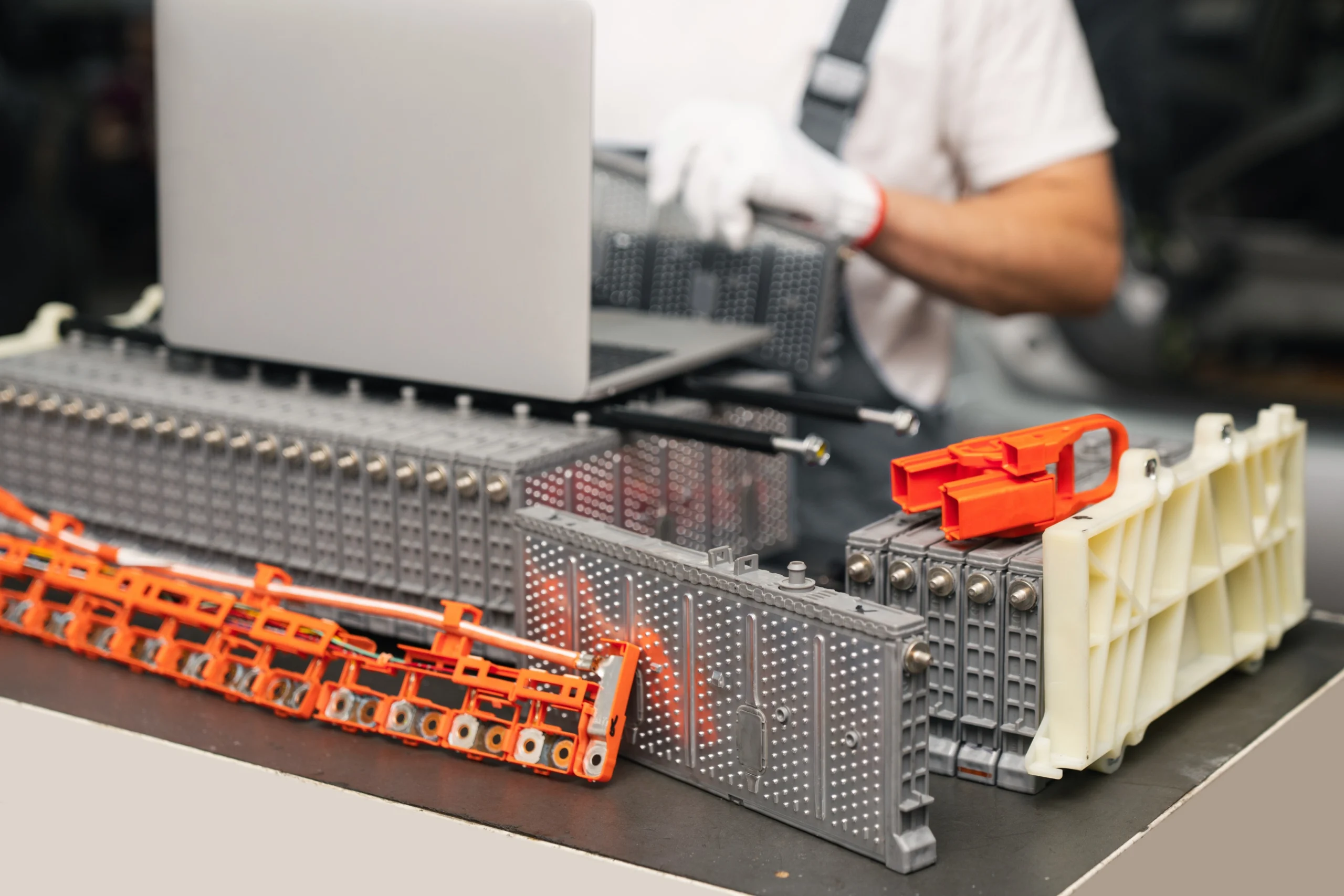

Catalytic Converter Recycling

Given the valuable materials used in catalytic converters, recycling has become an important industry. Recycling not only conserves precious metals but also reduces the environmental impact of mining and manufacturing new materials.

Recohub specializes in catalytic converter recycling, offering top-notch services to ensure efficient recovery of precious metals from used catalytic converters. By recycling your catalytic converters with Recohub, you contribute to environmental sustainability and gain value from your old components.

Why Choose Recohub for Catalytic Converter Recycling?

- Competitive Pricing: Recohub offers competitive catalytic converter price for your used catalysts, ensuring you get the best value.

- Expertise: With extensive experience in catalytic converter recycling, Recohub provides reliable and efficient services.

- Sustainability: Recycling with Recohub helps reduce the demand for newly mined precious metals, promoting environmental conservation.

In conclusion, the production of catalytic converters is a sophisticated process that integrates advanced materials and technologies to reduce vehicle emissions. As the automotive industry continues to evolve, so does the need for efficient catalytic converter recyclers. Recohub stands at the forefront of this effort, providing top-tier catalytic converter recycling services that benefit both the environment and your wallet.

For more information on catalytic converter recycling and to get a quote, contact us today!