Introduction

When it comes to vehicle emissions, both DPFs (Diesel Particulate Filters) and catalytic converters play essential roles in reducing harmful pollutants from diesel and petrol engines. Despite their similar purposes, these emission controls function differently, often leading to confusion. To clarify their distinct roles, this article will break down the main distinctions between the two.

What is a Catalytic Converter?

A catalytic converter is a vital component in the exhaust system of both diesel and petrol vehicles, designed to reduce harmful gases such as carbon monoxide, nitrogen oxides (NOx), and unburned hydrocarbons (HC) through a chemical reaction called oxidation. These highly polluting gases are transformed into less harmful substances like nitrogen, water vapor, and CO2 before being emitted through exhaust pipes. The honeycomb structure inside the catalytic converter contains precious metals such as platinum, palladium, and rhodium, facilitating this chemical reaction.

Catalytic converter recycling has become an essential industry due to the precious metals inside, causing catalytic converter prices and catalytic converter scrap prices to fluctuate significantly based on market demand and sensor technology involved. Recycling your catalytic converter can substantially reduce NOx emissions and contribute to environmental protection.

Catalytic converter recycling offers significant economic and environmental benefits. Specialized recycling centers recover valuable precious metals from spent catalytic converters, reducing the need for new mining activities and minimizing environmental impact. Recycling helps vehicle owners recoup part of their investment, especially when replacing the catalytic converter or during vehicle disposal.

The recycling process involves sophisticated extraction techniques to safely recover precious metals. As market prices fluctuate based on geopolitical factors and technological advancements, staying informed about catalytic converter scrap prices can help vehicle owners and recyclers maximize their economic benefits.

Catalytic converters contain precious metals more valuable than gold.

Inside every catalytic converter is a honeycomb structure coated with platinum, palladium, and rhodium—rare and expensive metals that drive the high recycling value of these components. This is why catalytic converter thefts have become increasingly common and why recycling them can offer substantial financial returns.

What is a DPF (Diesel Particulate Filter)?

Diesel engines specifically require a Diesel Particulate Filter (DPF) to manage emissions effectively. A DPF captures solid particulate matter such as soot, preventing these particles from entering the atmosphere. Unlike a catalytic converter that chemically converts harmful gases, a diesel particulate filter physically traps soot produced during combustion. Over time, the DPF can become clogged, reducing engine performance, triggering the engine light, and necessitating regeneration or cleaning.

DPF regeneration involves burning off accumulated soot at high temperatures, typically managed automatically by engine management systems utilizing a pressure sensor to detect when the DPF is clogged. Failure to address a clogged DPF promptly can lead to significant engine damage, impacting diesel cars’ overall performance. In extreme cases, vehicle owners might consider DPF delete or opt to install a new DPF to restore functionality fully.

How it Works – Diesel Particulate Filter (DPF)

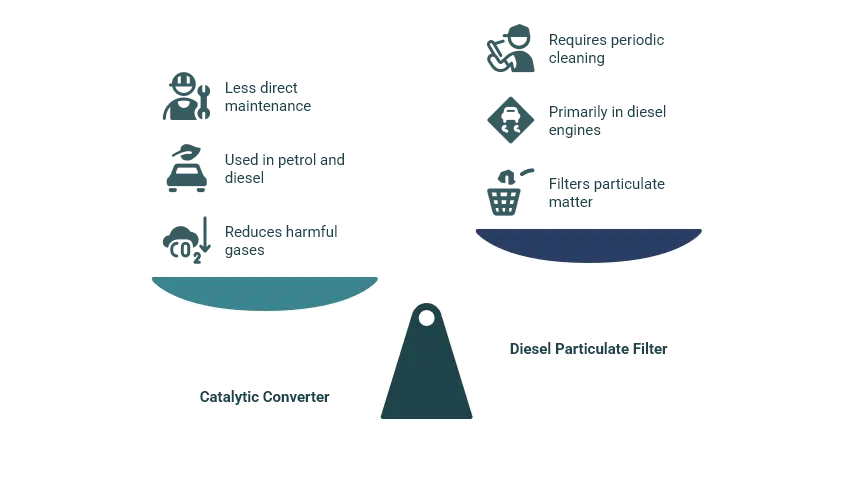

The Key Differences Between a DPF and a Catalytic Converter

- Function: A catalytic converter reduces harmful gases through oxidation, while a DPF filters out solid particulate matter to minimize pollution.

- Engine Type: Catalytic converters are commonly found in both petrol and diesel engines, whereas DPFs are primarily installed in diesel engines.

- Maintenance: DPFs require periodic regeneration or cleaning when clogged, whereas catalytic converters typically require less direct maintenance but can still degrade over time.

- Recycling Value: Catalytic converters hold greater recycling value due to the precious metals they contain, making them highly sought-after by catalytic converter recyclers.

Why Should You Care About These Differences?

Understanding the differences between a diesel particulate filter or catalytic converter is crucial, particularly for vehicle owners and businesses operating in the automotive and recycling industries. Knowledge of these components ensures appropriate vehicle maintenance, improves performance, and enhances environmental responsibility.

Vehicle owners should regularly inspect their exhaust system, EGR valve, exhaust manifold, heat shield, injectors, and sensors to maintain emission controls effectively. Mechanics can advise when a used DPF or catalytic converter requires replacement or regeneration, which helps manage emissions and reduce the risk of vehicle malfunction.

Whether driving petrol or diesel vehicles, being aware of your exhaust system components, such as DPF and catalytic converter, ensures responsible vehicle operation and compliance with environmental regulations. Knowing when a DPF is clogged or recognizing the importance of catalytic converter recycling can significantly impact vehicle performance, environmental footprint, and economic return.

If you have any questions regarding the recycling or valuation of your catalytic converter or used DPF, contact us. We specialize in compliant global recycling and purchasing services, ensuring that your components are handled responsibly and effectively.

Recycling catalytic converters helps reduce mining and environmental impact.

Recovering metals from used converters reduces the demand for new mining operations, which are environmentally intensive. This not only supports circular economy practices but also helps vehicle owners recoup part of their converter replacement costs.

FAQ

Yes, most modern diesel vehicles have both a catalytic converter to reduce harmful gases and a DPF to trap particulate matter like soot.

No, a catalytic converter reduces gas emissions through chemical reactions, while a DPF physically captures solid soot particles

No, they serve different purposes and usually work together in diesel engines to meet emissions standards.

Yes, a clogged DPF can lead to increased exhaust pressure and heat, potentially damaging the catalytic converter.

No, DPF cleaning machines are designed for soot removal and are not suitable for cleaning catalytic converters, which degrade differently.